Common Issues with the TPS54231DR and How to Troubleshoot Them

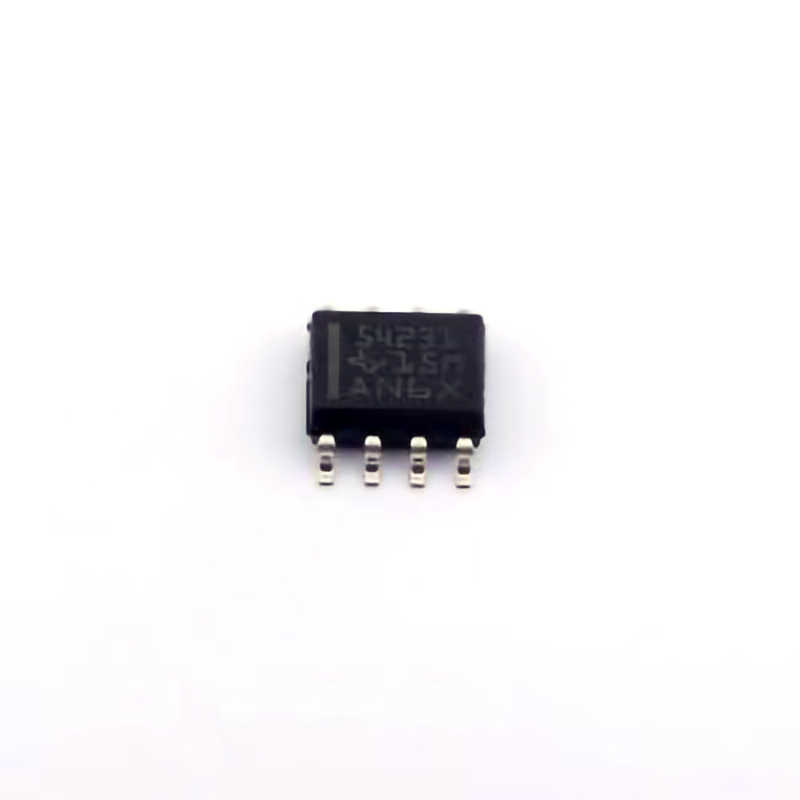

The TPS54231DR is a popular 3-A step-down regulator from Texas Instruments, widely used in a variety of applications such as Power supplies, battery-operated devices, and communication systems. While this integrated circuit (IC) is designed for ease of use and efficiency, users may occasionally encounter issues that hinder pe RF ormance. Understanding common problems and how to troubleshoot them is essential to maintaining the reliability and longevity of your system.

1.1 Power Output Voltage is Incorrect

One of the most common issues when using the TPS54231DR is an incorrect output voltage. This could manifest as an under-voltage or over-voltage situation, causing malfunctioning or instability in the powered device. The first step is to verify the following:

Possible Causes:

Incorrect Feedback Voltage: The TPS54231DR regulates the output voltage using feedback from the voltage divider network connected to the feedback pin (FB). If the resistors in this network are not correctly chosen or have drifted over time, the output voltage will not be as expected.

Poor Soldering of Feedback Components: Any poor solder joints or an open circuit in the feedback path can disrupt the regulation process.

Faulty Capacitors : capacitor s at the output or input of the IC are critical for stable operation. A damaged or poorly specified capacitor could affect the voltage regulation loop.

Troubleshooting Steps:

Measure the Feedback Pin Voltage: Use an oscilloscope or multimeter to check the voltage on the feedback pin. Compare this with the internal reference voltage (usually around 0.8V for the TPS54231DR). A discrepancy suggests an issue with the feedback resistor network.

Inspect the Feedback Resistor Network: Ensure the feedback resistors are correctly rated and positioned. Verify their values using a multimeter to confirm they are within the specified range.

Check Capacitors: Use an ESR (Equivalent Series Resistance ) meter to check the capacitors’ health. Replacing suspect capacitors with components of the correct value can often solve output voltage issues.

1.2 Excessive Heat Generation

Heat dissipation is a crucial factor in the performance of voltage regulators. The TPS54231DR is designed to operate efficiently, but excessive heat generation can still occur under certain conditions. Overheating can damage the IC or reduce its efficiency.

Possible Causes:

High Input Voltage: If the input voltage is significantly higher than the output voltage, the IC will need to dissipate the excess energy as heat. This is particularly problematic in situations where the input voltage is much higher than necessary for the required output.

Poor PCB Layout: An improper layout can lead to hotspots and poor heat sinking, especially if the power traces are too narrow or if there’s insufficient copper area for heat dissipation.

Excessive Load: A high current load can cause the IC to heat up as it tries to supply power beyond its rated capacity.

Troubleshooting Steps:

Check Input and Output Voltage Difference: Ensure the input voltage is within the recommended range and as close as possible to the output voltage to minimize heat dissipation.

Examine PCB Layout: Look for good copper pour areas around the IC, particularly on the ground and power planes. Ensure that power traces are wide enough to handle the current. Use a thermal camera to identify hot spots.

Monitor Load Current: Check the current draw of the load. If the load exceeds 3A, consider using a higher-rated regulator or add a heat sink to the IC to improve thermal performance.

1.3 Inconsistent Output Voltage (Ripple and Noise)

Voltage ripple and noise are common issues in power supplies, especially when the regulator is under load. High ripple and noise can affect sensitive components like microcontrollers or RF circuits.

Possible Causes:

Insufficient Output Capacitors: The TPS54231DR requires appropriate output capacitors to filter high-frequency noise. Using incorrect capacitor types (such as low-ESR or too small a value) can lead to higher ripple.

Poor Grounding: A poor ground plane or improper grounding can cause noise to couple into the output, degrading voltage stability.

PCB Layout Issues: If the power and ground traces are not designed optimally, electromagnetic interference ( EMI ) can cause oscillations and noise at the output.

Troubleshooting Steps:

Check Capacitor Specifications: Ensure that the output capacitors meet the specifications provided in the datasheet. Capacitors with low ESR are preferred, as they help filter high-frequency noise.

Improve Grounding: Ensure the ground plane is solid and continuous, with short and wide connections to minimize noise coupling. Avoid shared ground paths between noisy and sensitive circuits.

Use Proper Layout Techniques: Keep power and signal traces separate. Avoid running high-current traces close to sensitive components, and place decoupling capacitors as close to the IC pins as possible.

1.4 No Output Voltage (Regulator Not Starting)

Sometimes, users may encounter a situation where the regulator fails to start and no output voltage is generated. This can happen for various reasons, and troubleshooting requires a systematic approach.

Possible Causes:

Incorrect Enable Pin Configuration: The enable pin (EN) is crucial for turning the regulator on. If the enable pin is held low or not connected, the IC will remain off.

Faulty Components or Connections: Damaged components such as resistors, capacitors, or even the IC itself could prevent proper startup.

Improper Shutdown Behavior: If the IC is inadvertently held in shutdown mode (through incorrect input voltage or external logic), the output voltage will not be present.

Troubleshooting Steps:

Verify Enable Pin Voltage: Check the voltage at the enable (EN) pin. It should be pulled high (typically above 1.2V) to turn the regulator on. If the enable pin is low, adjust your circuit or control logic accordingly.

Inspect the Power Components: Look for any signs of physical damage or poor connections, especially around the input and feedback pins. A broken or damaged part could prevent the regulator from starting.

Confirm Startup Conditions: Ensure the input voltage is within the proper range for the TPS54231DR to operate correctly, typically between 4.5V and 60V.

Advanced Troubleshooting Techniques and Best Practices

While basic troubleshooting techniques are often sufficient to resolve common issues with the TPS54231DR, more advanced diagnostic methods and preventive measures can help ensure reliable long-term performance. In this section, we explore advanced troubleshooting strategies and best practices to optimize the design and operation of the regulator.

2.1 Advanced Oscilloscope Techniques for Diagnosing Power Supply Issues

An oscilloscope is an indispensable tool for diagnosing power supply issues, especially when it comes to detecting ripple, noise, and transient behavior in voltage regulators like the TPS54231DR.

Advanced Tips:

Measure Ripple at the Output: Use a high-frequency oscilloscope probe to check for ripple at the output. This will help identify any high-frequency noise or spikes that may affect the performance of downstream components.

Check the Switching Node: The TPS54231DR uses a switching mechanism to regulate the output. By probing the SW pin, you can observe the switching waveform, which will indicate whether the regulator is functioning properly. A clean, regular waveform suggests normal operation, while irregularities or a lack of switching could point to issues with the inductor or other components.

Capture Transients: High-speed oscilloscopes with deep memory can capture transient events that might be difficult to detect with a standard multimeter. Use these capabilities to look for any rapid voltage fluctuations that could cause instability in the system.

2.2 Thermal Management and IC Protection

Effective thermal management is crucial for maintaining the performance and lifespan of the TPS54231DR. Overheating not only leads to inefficiency but can also cause permanent damage to the IC.

Best Practices:

Use Thermal Via Array: If your PCB has multiple layers, ensure that thermal vias are placed under the IC to conduct heat away from the component. This helps to distribute the heat across the board.

Use External Heat Sinks or Copper Planes: In applications with high load currents or significant input-output voltage differences, consider adding external heat sinks or increasing the size of the copper plane underneath the IC to improve heat dissipation.

Monitor Junction Temperature: Always monitor the junction temperature of the TPS54231DR during operation. Texas Instruments provides thermal data in the datasheet that can be used to calculate the expected thermal behavior of the IC based on its power dissipation and the ambient temperature.

2.3 Design for Stability: Capacitor Selection and Layout

As mentioned earlier, capacitor selection is crucial for the performance of the TPS54231DR, particularly with regard to output stability and noise filtering.

Design Considerations:

Choose Low-ESR Capacitors: Low-ESR capacitors at both the input and output of the IC help stabilize the voltage and filter out high-frequency noise. Ceramic capacitors are often recommended for this purpose.

Optimize Placement of Decoupling Capacitors: For best results, place the decoupling capacitors as close as possible to the IC pins. This minimizes inductance and resistance that could degrade performance.

Ensure Proper Value Matching: Ensure that the values of the capacitors are within the recommended range outlined in the datasheet to avoid any instability in the feedback loop.

2.4 Improving EMI and Noise Immunity

Electromagnetic interference (EMI) can affect the performance of the TPS54231DR, especially in sensitive applications. Proper layout and component selection can help reduce EMI and improve the regulator's immunity.

Best Practices:

Use Shielding and Ground Planes: Incorporate shielding or a solid ground plane to prevent noise from coupling into the power supply lines.

Minimize Switching Noise: Keep the switching node short and thick to minimize noise. Use ferrite beads or inductors in series with the input and output to suppress high-frequency switching noise.

By following these troubleshooting techniques and best practices, you can maximize the reliability and efficiency of your TPS54231DR-powered system, minimizing downtime and ensuring optimal performance. Whether you are designing a new circuit or troubleshooting an existing one, this guide provides a comprehensive roadmap for achieving power conversion excellence.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.